Factory Tolerance Restoration training equips technicians to accurately adjust vehicle components post-damage, using specialized tools and schematics to interpret manufacturer specifications. This process combines theoretical knowledge and hands-on practice on diverse machinery, from heavy equipment to precision instruments, ensuring precise repairs meeting factory standards in collision repair centers, with a focus on paintless dent repair techniques and advanced equipment.

In today’s manufacturing landscape, efficient factory tolerance restoration is vital for maintaining machine precision and ensuring optimal production. This article explores how technicians are trained to excel in this critical task. We delve into understanding the nuances of factory tolerance restoration from a technician’s perspective, examining effective training methods that blend theoretical knowledge with hands-on practice. By refining skills through real-world scenarios, technicians gain the expertise needed to navigate complex restoration processes, ultimately enhancing production efficiency and quality control.

- Understanding Factory Tolerance Restoration: A Technician's Perspective

- Training Methods for Restoring Machine Precision

- Hands-On Practice: Real-World Scenarios for Skill Refinement

Understanding Factory Tolerance Restoration: A Technician's Perspective

Factory Tolerance Restoration is a critical skill for technicians to master, as it involves bringing damaged vehicles back to their original specifications and ensuring seamless performance. From a technician’s perspective, this process demands an in-depth understanding of vehicle manufacturing tolerances—the precise dimensions and allowances that determine how well various components fit together. It’s about identifying the root cause of a problem, whether it’s a misaligned panel in a car body restoration or a faulty sensor in bumper repair services, and then making accurate adjustments to restore optimal functionality.

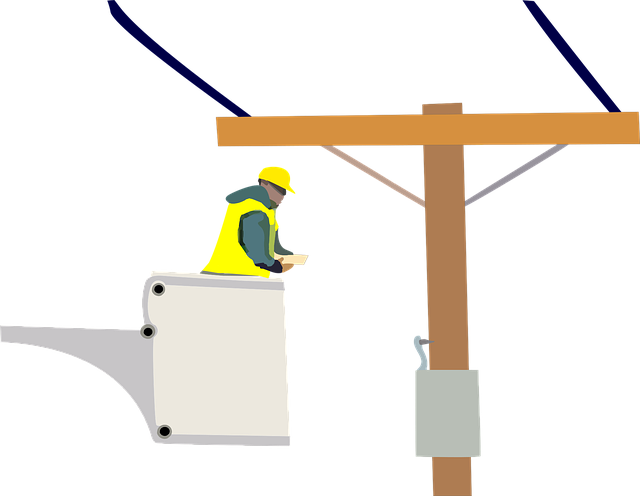

Technicians are trained to use specialized tools and equipment to measure and adjust these tolerances, often with a focus on precision and safety. They learn to interpret complex schematics and work instructions to navigate the intricate labyrinth of a vehicle’s design, ensuring that every repair or restoration is carried out with meticulous care. This training equips them to handle a wide range of vehicles, from simple fender benders requiring car repair services to more intricate car body restoration projects, ultimately contributing to the overall quality and reliability of factory-like repairs.

Training Methods for Restoring Machine Precision

Technicians undergo specialized training to master the art of factory tolerance restoration, a process crucial for ensuring precision in industrial machinery. This training involves a blend of theoretical knowledge and hands-on practice. They learn about the intricate mechanisms that dictate machine accuracy, enabling them to identify and rectify any deviations from the manufacturer’s specifications.

The training methods include simulations that replicate real-world scenarios, allowing technicians to refine their skills in a controlled environment. They practice on diverse machinery, from heavy industrial equipment to precision instruments, gaining versatility in auto maintenance and even specialized tasks like vehicle dent repair or car paint services. This comprehensive approach ensures they are prepared to tackle various challenges related to factory tolerance restoration across different sectors.

Hands-On Practice: Real-World Scenarios for Skill Refinement

Hands-on practice is an integral part of training technicians for factory tolerance restoration, a process that ensures vehicles meet precise manufacturing standards. Trainees engage in real-world scenarios at dedicated collision repair centers, where they learn to identify and rectify subtle imperfections using advanced tools and techniques. This immersive experience allows them to refine their skills in paintless dent repair, a key aspect of factory tolerance restoration, which involves repairing damage without repainting the entire vehicle.

By working on actual vehicles, technicians gain practical knowledge about panel gaps, alignment, and surface smoothness. They learn to use specialized equipment like handheld tools and sensors to measure and adjust various components, ensuring every part adheres to the manufacturer’s specifications. This hands-on approach not only enhances their understanding of factory tolerance restoration but also prepares them to tackle diverse vehicle models and body types encountered in a professional automotive repair service environment.

Factory tolerance restoration is a critical skill that requires specialized training for technicians. By understanding the nuances of machine precision and employing effective training methods, including hands-on practice in real-world scenarios, technicians can master this art. This ensures optimal equipment performance and contributes to overall operational efficiency. Embracing these training strategies empowers technicians to tackle factory tolerance restoration challenges head-on, ultimately driving industrial success.